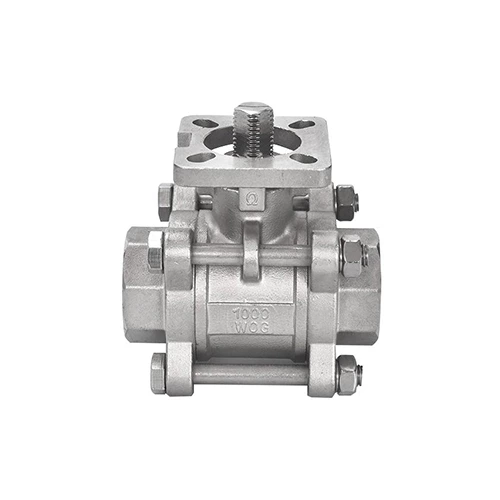

Analysis Of Common Materials And Heat Treatment Of Ball Valves, Gate Valves, Check Valves, Globe Valves, And Filter Valve Bodies

Ball Valve, gate valve, check valve, stop valve, filter valve body commonly used materials are as follows:

1. Gray cast iron, suitable for low-pressure valves with working temperature between -15~+200℃ and nominal pressure PN≤1.6MPa.

2. Blackheart malleable cast iron, suitable for medium and low pressure valves with working temperature between -15~+250℃ and nominal pressure PN≤2.5MPa.

3. Ductile iron, suitable for medium and low pressure valves with working temperature between -30~+350℃ and nominal pressure PN≤4.0MPa.

4. Carbon steel (WCA, WCB, WCC), suitable for medium and high pressure valves with working temperature between -29~+425℃, of which 16Mn and 30Mn have working temperature between -40~+450℃, and are often used to replace ASTMA105.

5. Low temperature carbon steel (LCB), suitable for low temperature valves with working temperature between -46~+345℃.

6. Alloy steel (WC6, WC9), suitable for high temperature and high pressure valves with working temperature between -29~+595℃ for non-corrosive media; WC5, WC12 are suitable for high temperature and high pressure valves with working temperature between -29~+650℃ for corrosive media.

7. Austenitic stainless steel, suitable for valves with working temperature between -196~+600℃ for corrosive media.

8. Monel alloy, mainly suitable for valves with hydrogen and fluorine media.

9. Cast copper alloy, mainly suitable for valves for oxygen pipelines with working temperature between -273~+200℃.

The heat treatment process of valve body blank is as follows according to different materials:

1. Heat treatment of gray cast iron.

In order to achieve different purposes, gray cast iron can be subjected to different heat treatments after casting. In valve production, the heat treatment processes commonly used for gray cast iron valve bodies and other parts after casting are: heat aging to eliminate casting stress and high temperature annealing to eliminate free cementite. Heat aging is a necessary process. High temperature annealing is only used to replace heat aging when the chemical composition and casting cooling rate are improperly controlled during casting, resulting in the presence of primary cementite in the structure after casting.

2. Heat treatment of carbon cast steel.

Steel castings have large casting residual stress after casting, and sometimes the structure of steel castings is coarse, and even overheated structures appear. These all affect the dimensional stability of steel castings, reduce the mechanical properties of steel and are not conducive to cutting. In order to eliminate casting stress, refine the structure, improve mechanical properties and improve cutting processability, annealing or normalizing + tempering treatment is often used for carbon steel valve bodies and other parts in valve production after casting.

3. Heat treatment of austenitic stainless acid-resistant steel.

The main defect of austenitic stainless acid-resistant steel is that it is easy to produce intergranular corrosion. Generally, certain heat treatment measures can be taken to prevent it. In valve production, the heat treatment processes commonly used for austenitic stainless acid-resistant steel valve bodies and other parts are: solution treatment (quenching), stabilization treatment and deep cryogenic treatment.

4. Heat treatment of martensitic heat-resistant steel.

Martensitic heat-resistant steel should be annealed in time after casting to prevent cracks, and the annealing and heat preservation time should be sufficient (generally 4 to 8 hours). The purpose of annealing martensitic heat-resistant steel is to eliminate stress, recrystallize, refine grains, reduce hardness, improve cutting performance, and prepare the organization for final heat treatment.

The final heat treatment of martensitic heat-resistant steel adopts normalizing + tempering treatment.

5. Heat treatment of carbon steel.

Take the No. 35 forged steel valve body as an example of the heat treatment of carbon steel. The No. 35 steel valve body needs to be normalized after forging, and its final heat treatment should be carried out according to the provisions of the valve manufacturing technical documents, and generally tempering treatment is required.