Are These Advantages Of American Standard Ball Valves Attractive Enough To You?

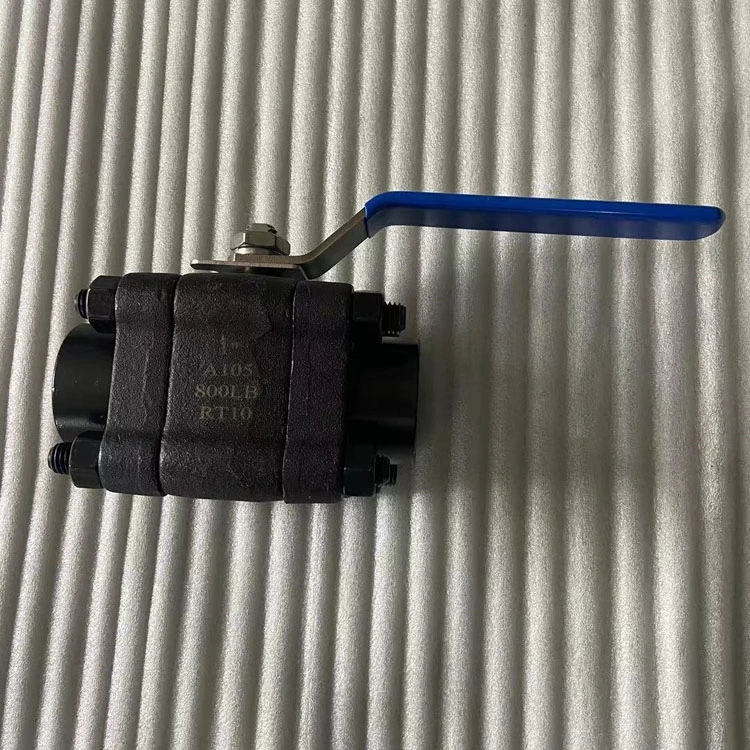

Ball Valve and flange gate valve belong to the same type of valve. The difference between the two is the closing part. The closing part of the American standard ball valve is a sphere, which is opened and closed by rotating the sphere around the center line of the valve body. So do you know what advantages the American standard ball valve has?

(1) The ball valve has a simple structure, small size and light weight.

(2) The fluid resistance is small, and its resistance coefficient is equal to that of the pipe section of the same length.

(3) The material is tight and reliable. The sealing surface material is plastic, which has good sealing performance and is widely used in vacuum systems.

(4) Easy to operate and fast to open and close. The ball valve only needs to be rotated 90° from fully open to fully closed, which is conducive to long-distance control.

(5) Easy to maintain, because the ball valve has a simple structure and its sealing ring is generally movable, which is very convenient to disassemble and replace.

(6) Not easy to corrode. When the ball valve is fully open or fully closed, the ball and valve seat sealing surface are isolated from the medium, and the medium will not cause erosion of the valve sealing surface when passing through.

(7) Widely used, the diameter of the ball valve ranges from a few millimeters to several meters; it can be used from high vacuum to high pressure.

There are also many valve body materials for ANSI ball valves: WCB, ZG1Cr18Ni9Ti, ZG1Cr18Ni12Mo2Ti, CF8 (304), CF3 (304L), CF8M (316), CF3M (316L), Ti. Different materials can be used for different media: such as water, steam, oil, nitric acid, acetic acid, oxidizing media, urea and other media.

So are these advantages of ANSI ball valves attractive to you?