Common Classification And Use Of Stainless Steel Valves

Today I will explain to you the relevant knowledge of Check Valve. Stainless steel valves have entered industrial use due to their advantages such as green environmental protection, and have become valve products that must be purchased in the pipeline field of various industries. Therefore, before purchasing, customers must ask merchants to provide production and factory certificates of various stainless steel valves. They can also be tested with spectrometers. Spectrometers are widely used due to their high precision and wide range of applications. Some 304 and 316L valves are mainly tested by this equipment, which can reduce the purchase of unqualified products.

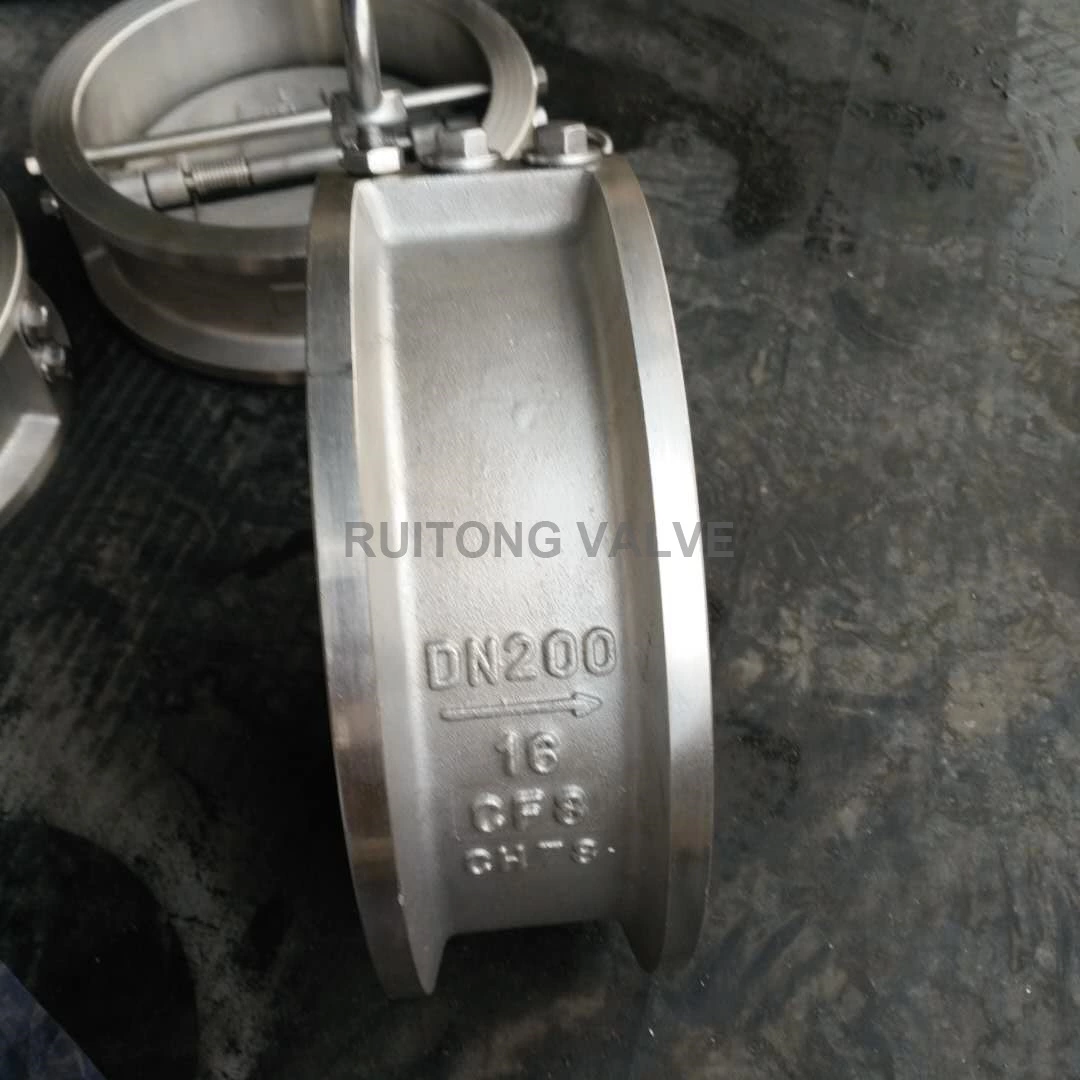

Types of stainless steel valves

Common ones include: stainless steel gate valves, stainless steel filters, etc., and a variety of materials are available for selection.

Classification of stainless steel valves

1. The main features of folding stainless steel plug valves

1. It can be made into double hanging point opening and closing.

2. Strong adaptability;

3. Good sealing and water-stopping performance;

4. Good anti-corrosion performance;

2. The main features of folding stainless steel ball valves

1. Small fluid resistance;

2. Small size and light weight;

3. Tight and reliable, good sealing;

4. Convenient operation, quick opening and closing;

5. Convenient maintenance, simple structure;

6. Not easy to corrode in full open or full closed state;

7. Wide range of applications.

Uses of stainless steel valves

Widely used in petroleum, liquefied gas pharmaceutical, electronic industry and other fields. The working pressure can be from 0.0013~1000MPa, and the temperature can be from -269℃~1430℃.

How to check the intergranular corrosion of stainless steel valves

(1) Sulfuric acid evaporation test method (L method);

(2) Sulfuric acid evaporation test method (T method);

(3) Nitric acid evaporation test method (X method);

(4) Oxalic acid electrolytic etching test method (C method);

(5) Nitric acid constant temperature test method (F method).

Stainless steel valve installation

1. To avoid damage to these parts, they should be tied to the flange.

2. Before installation, check the valves one by one in detail, such as: specifications and models.

3. When installing flange pneumatic valves, pay attention to tighten the bolts evenly, not too loose or too tight.

4. Wrap the sealing packing on the pipe thread to avoid affecting the flow of the medium.

5. The pipeline must be cleaned to avoid failure.