Future Development Trend Of Global Valves

With the development of large-scale complete sets of technology abroad, a series of new complete sets of equipment and single machines have emerged. The characteristics of the development of new complete sets of equipment related to Ball Valve are large-scale, high-parameterization, high-performance automation and complete sets, which are adapted to the control methods of these complete sets of equipment. In the past 20 years, the control methods of foreign valves have also developed greatly. In addition to general manual, motorized, electric, pneumatic, and hydraulic transmission, the varieties of valves with electro-hydraulic linkage, gas-liquid linkage, and automatic control are increasing, and there is a trend of further development.

For example, oil refining equipment. The largest refinery is 36.4 million tons/year (Virgin Islands in the Caribbean Sea), 30 million tons/year (Venezuela). At present, there are nearly 30 refineries with more than 20 million tons/year; the processing capacity of the largest unit refining pressure reduction unit reaches 24 million tons/year, the catalytic cracking unit reaches 8.24 million tons/year, and the hydrocracking unit reaches 3.2 million tons/year. The large-scale equipment forces the valves to become larger and larger, and the control method also begins to develop in the direction of automation.

In recent years, long-distance pipelines have developed rapidly. The main reasons are: first, low cost, only equivalent to 1/3 of railway transportation; second, buried underground, not easy to be damaged; third, pipeline construction speed is fast and investment is low. Therefore, the demand for valves for long-distance pipelines has increased greatly in recent years. The maximum unit capacity of power generation equipment is 1.3 million kW for double-shaft thermal power units, 1.2 million kW for single-shaft thermal power units, and 1.3 million kW for nuclear power units.

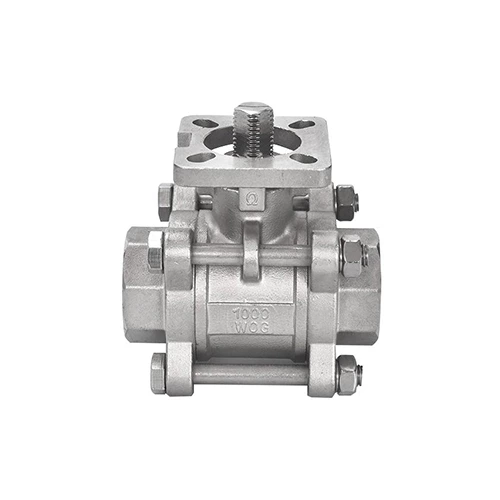

Among the valves matched with these complete sets of equipment, the largest flat gate valve has a diameter of 1620mm and 2000mm; the largest butterfly valve has a diameter of 9750mm; the largest ball valve has a diameter of 3050mm, and the weight of the valve without the drive device reaches 184 tons; the largest water gate valve has a diameter of 2750mm and a pressure of 9MPa.

The economic effects of large-scale equipment can be summarized as follows: first, improve production efficiency, second, reduce infrastructure investment, and third, reduce the consumption of raw materials. Compared with a refinery with an annual processing capacity of 5 million tons and a refinery with an annual processing capacity of 1 million tons, the investment per ton of product production capacity is reduced by 50%. Compared with two 3 million ton/year refineries, the investment of a 6 million ton/year refinery is only 69% of the latter, the steel consumption is 53%, the land area is 54%, the production cost is 75%, while the labor productivity is increased to 170%.