How Much Do You Know About Flange Stop Valves And Other Sealing Performance Requirements?

Stainless Globe Valve and other sealing performance requirements, how much do you know? Before answering this question, let's first understand what makes a flange stop valve!

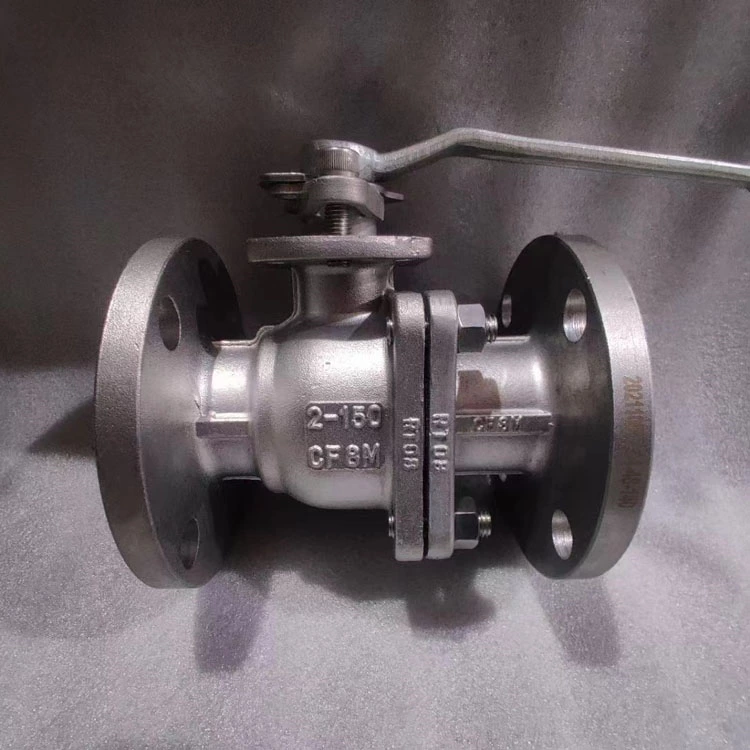

Stop valves are a common and common type of valves. When some parts of the stop valve are connected in a flanged manner, this is a flange stop valve. If the flange stop valve is distinguished by the sealing method, it is a kind of mandatory sealing valve. The characteristic of this sealing method is that when closing the valve, a certain pressure needs to be applied to the valve disc to force the sealing surface to ensure that there is no leakage. Therefore, the sealing surface material of the flange stop valve is generally made of metal materials with high hardness and strength to ensure that there is no damage when the valve disc applies pressure.

As a kind of stop valve, the flange stop valve has almost the same characteristics and structure as other stop valves. The difference mainly lies in the different connection methods, so the method of distinguishing stop valves can also be based on the connection method, such as threaded stop valves, welded stop valves, etc.

The sealing performance of the flange stop valve refers to the ability of each sealing part in the valve to prevent the leakage of the medium, and this ability can be said to be a very important performance indicator in the valve. The sealing parts of flange stop valves are generally divided into three parts, namely the seal between the opening and closing parts and the valve seat, the seal between the packing and the valve stem, and the seal between the valve body and the valve cover.

If the seal between the opening and closing parts and the valve seat leaks, it is generally called internal leakage, that is, the valve is not closed tightly in the usual sense, which will directly affect the flange stop valve's ability to cut off the medium. Therefore, for valves such as flange stop valves, internal leakage is often a very serious performance failure. The problems with the latter two seals are called external leakage, that is, the medium leaks from the inside of the valve to the outside of the valve, causing damage to the medium and causing certain impacts on the environment. If the medium is a flammable and explosive substance, it may also cause certain safety hazards.