It Is Best For High-rise Residents To Install Check Valves

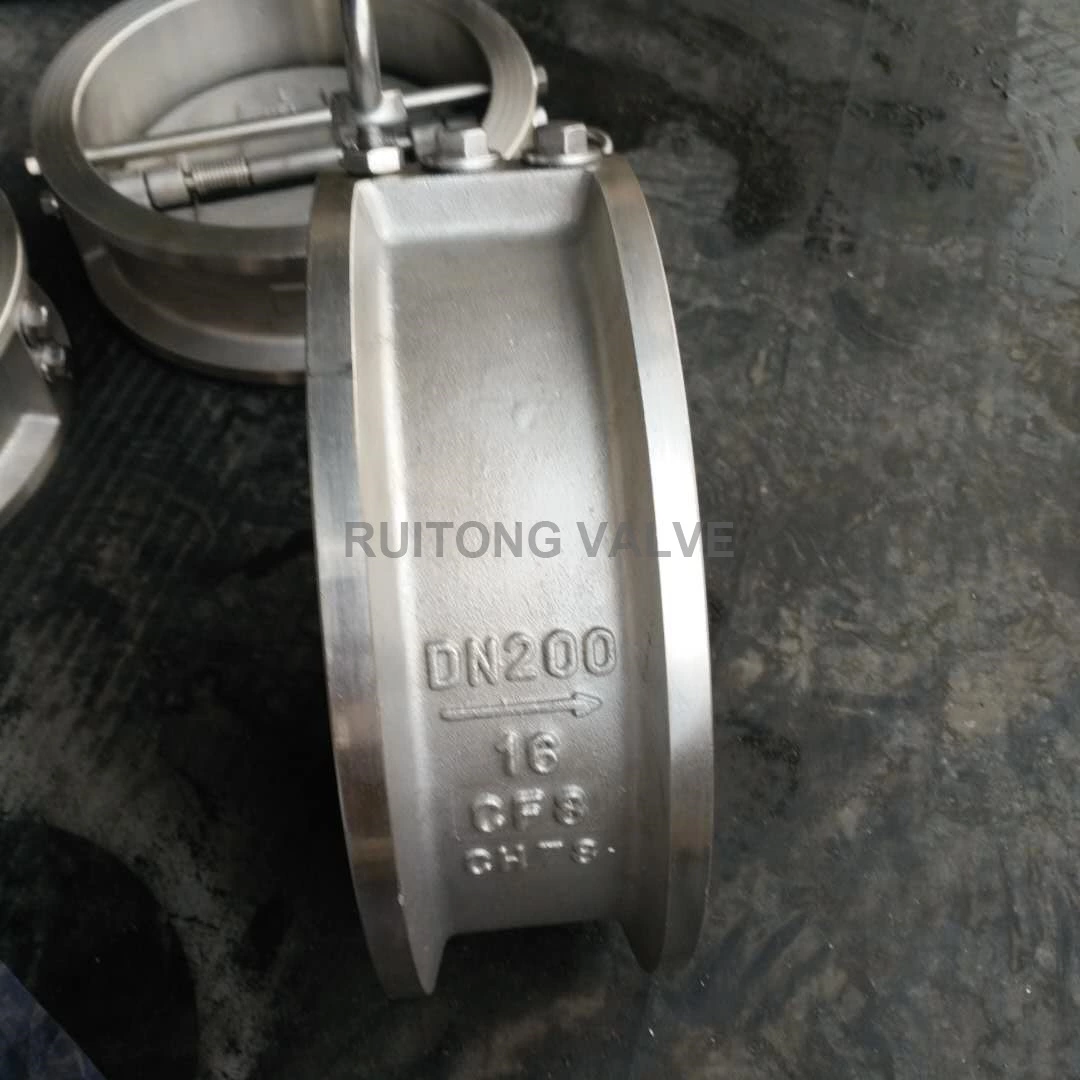

Many cities across the country have had water meters in high-rise residential buildings that have "self-rotated". In addition to the water meter's own problems and pipeline leakage, most water meters "self-rotate" because of air pressure and unstable pressure in the pipeline after the secondary pressurized water supply. This problem can be solved by installing Check Valve. "The idling caused by the pressure difference can be solved by installing a check valve in front of the meter, which can prevent water from flowing back. When the water pressure increases, the water meter rotates forward; when the pressure decreases, the check valve will automatically close and the water meter will not rotate. When the pressure increases again, as long as the pressure is not higher than the pressure in the check valve, the water meter will not rotate again." Check valves are also called one-way valves or non-return valves. Their function is to prevent the medium in the pipeline from flowing back. The bottom valve of the water pump suction valve also belongs to the check valve category. The valve that opens or closes automatically by the flow and force of the medium to prevent the medium from flowing back is called a check valve. Check valves belong to the automatic valve category, which are mainly used in pipelines where the medium flows in one direction, and only allow the medium to flow in one direction to prevent accidents. Usually, the fluid opens the valve flap under pressure and flows from the inlet side to the outlet side. When the pressure on the inlet side is lower than that on the outlet side, the valve flap automatically closes the channel under the action of the fluid pressure and its own gravity to prevent the fluid from flowing back. According to the different movement modes of the valve flap, check valves are mainly divided into three types: lift type, swing type and butterfly type. The valve body of the lift check valve is similar to that of the stop valve, and its fluid resistance is relatively large. This type of check valve is a high-pressure small-diameter check valve, and a spherical valve flap is often used. The swing check valve has less resistance to the fluid and is generally suitable for small and medium-diameter, low-pressure and large-diameter pipelines. Multiple valve flaps are often set on the channel partition of the valve to become a multi-flap type. The shape of the butterfly check valve is similar to that of the butterfly valve. It has a simple structure and low resistance to the fluid. If the check valve is closed too quickly, it may cause liquid hammer in the liquid pipeline, generate noise, and even cause damage to the valve parts. To avoid this situation, a check valve with a buffer function can be selected when necessary to extend the closing time.

The following matters should be noted during installation:

1. Do not allow the check valve to bear weight in the pipeline. Large check valves (aetv One-way valve): should be supported independently so that they are not affected by the pressure generated by the pipeline.

2. During installation, pay attention to the direction of medium flow should be consistent with the direction of the arrow marked on the valve body.

3. Lifting vertical flap check valve (One-way valve): should be installed on vertical pipelines.

4. Lifting horizontal flap check valve should be installed on horizontal pipelines.