The Role Of The Stop Valve

Globe Valve is used to cut off the flow of the medium. The stop valve is suitable for occasions that need to be opened frequently. It is most commonly used in chemical production.

The sealing parts of the stop valve are the valve disc and the valve seat. In order to make the stop valve close tightly, the matching surface of the valve disc and the valve seat should be ground or gasketed. The sealing surface can also be inlaid with corrosion-resistant and wear-resistant materials such as bronze and stainless steel. The valve disc and the valve stem of the stop valve are connected flexibly to facilitate the close fit of the valve disc and the valve stem.

What is the function of the stop valve - the advantages and disadvantages of the stop valve

The lifting and lowering of the valve disc of the stop valve is generally controlled by the valve stem. The upper part of the valve stem of the stop valve is the hand wheel, and the middle part is the thread and packing sealing section. The function of the packing is to prevent the medium inside the valve body from leaking along the valve stem.

The main function of the stop valve in the chemical pipeline is to cut off or connect the fluid. The stop valve has a better flow regulation than the gate valve, but the stop valve cannot be used to adjust the pressure and flow for a long time. Otherwise, the sealing surface of the stop valve may be eroded and corroded by the medium, destroying the sealing performance.

The stop valve can be used for water, steam, compressed air and other pipelines, but it is not suitable for medium pipelines with high viscosity, easy to coke, and easy to precipitate, so as not to damage the sealing surface.

The working principle of the stop valve is that the valve disc of the stop valve moves vertically along the center line of the valve seat, relying on the spinning of the valve stem thread, so that the valve disc sealing surface of the stop valve and the valve seat sealing surface are tightly fitted together, thereby cutting off the flow of the medium.

Advantages and disadvantages of the stop valve

Advantages of the stop valve

The stop valve has a small working stroke and a short opening and closing time.

The stop valve has good sealing, small friction between the sealing surfaces, and a long service life.

The stop valve has good adjustment performance.

Disadvantages of the stop valve are

The installation length of the stop valve is large, and the resistance to the flow of the medium is large.

The structure of the stop valve is relatively complex, and it is difficult to manufacture and maintain.

The fluid of the stop valve passes through the valve seat from bottom to top, with large resistance, and the force required for opening and closing is large.

The stop valve is generally not suitable for media with particles, high viscosity, and easy to coke.

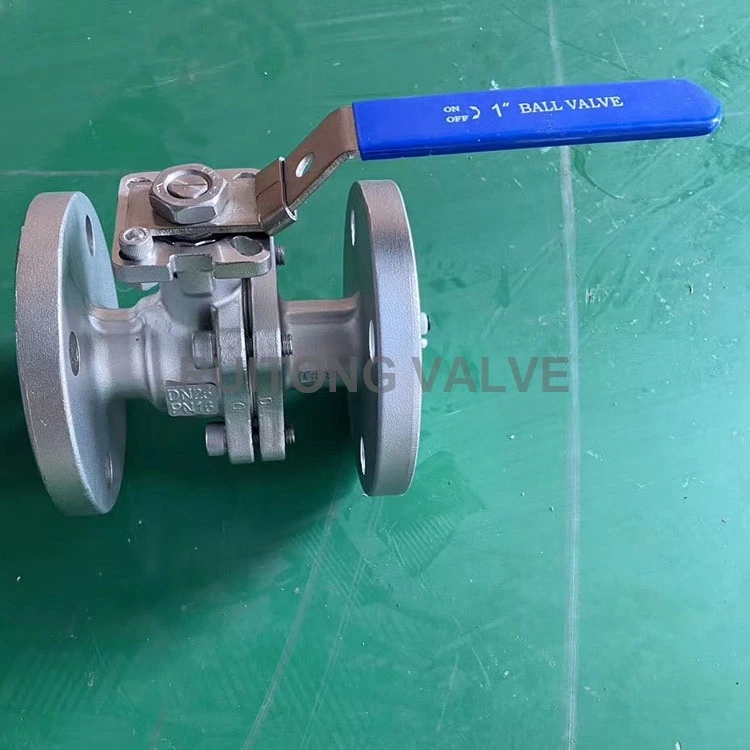

Stop valves are often used in pipelines that need to be fully opened and fully closed, and steam pipelines are more commonly used. The connection between the stop valve and the pipeline can be threaded or flanged. Flow is the most commonly used concept in pipeline design, so what is flow? What is the unit of flow?

Flow actually refers to the volume and weight of the fluid flowing through the pipeline per unit time.

Flow is generally represented by the symbol Q, and the unit of flow is often expressed in liters/second or cubic meters/hour.

Because the weight of 1 liter of clean water is 1 kilogram, and the weight of 1 cubic meter of clean water is exactly 1 ton, which is 1000 kilograms, so people often write liters/second as kilograms/second and cubic meters/hour as tons/hour.

If the flow is measured by volume, then the flow is called volume flow, which is also the concept used in most cases. In the international unit SI, the standard unit of volume flow is cubic meters per second (m3/s).

If the amount of fluid is measured by mass, then the flow rate is called mass flow rate. In the International System of Units, the unit of mass flow rate is called kilograms per second (kg/s).

Flow unit conversion

1 hour = 3600 seconds

1 ton = 1000 kilograms = 1000 liters

1 liter/second = 3.6 cubic meters/hour = 3.6 tons/hour

How to convert the two units of flow? If the value of liters/second is known, then just multiply this value by 3.6 to get the value of tons/hour; on the contrary, if we already know the value of tons/hour, then just divide this value by 3.6 to get the value of liters/second.