What Are The Characteristics And Uses Of American Standard Ball Valves?

Everyone should be familiar with Ball Valve. As for the characteristics and uses of the American standard ball valve, I believe you are also familiar with it. However, we still want to introduce the characteristics and uses of the American standard ball valve.

Characteristics of the American standard ball valve: Valve stem anti-flying structure: When the medium passes through the valve, the pressure in the valve body cavity may push the valve stem out. To prevent this from happening, a boss structure is set at the bottom of the valve stem, so that even if the packing, thrust bearing is burned or other reasons cause the packing to be damaged during a fire, the medium pressure in the valve body will make the valve stem boss and the valve body seal in close contact, preventing a large amount of medium from leaking from the damaged packing part;

Anti-static device: When operating the valve, due to the friction between the ball and the non-metallic material valve seat such as polytetrafluoroethylene, static electricity will be generated and accumulated on the ball. In order to prevent the generation of static sparks, an anti-static device is specially installed on the valve to conduct the generated static electricity;

Fireproof structure: The valve seat of our company's floating ball valve adopts a unique structure. When a fire occurs and the non-metallic sealing surface material is burned, the metal ring uses the elastic force of the spring to push the valve seat to fit and seal with the ball, thereby preventing the spread of fire and the outflow of the medium;

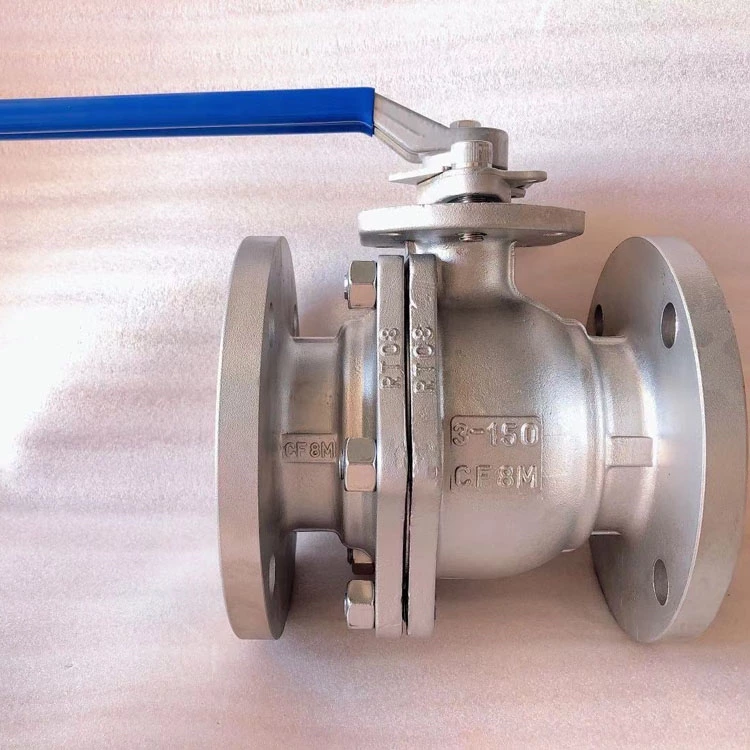

No leakage structure of the middle flange: The connection between the valve body and the left body is sealed by a gasket. In order to prevent the seal leakage caused by fire, high temperature or vibration, the valve body and the left body are specially designed to be in metal-to-metal contact to form a stop flange to ensure no leakage;

Automatic pressure relief structure: When the medium retained in the middle cavity of the valve changes due to factors such as the pipeline system pressure or the medium temperature, resulting in an abnormal increase in the pressure in the middle cavity, the middle cavity medium can rely on its own thrust to push the valve seat and automatically release the pressure, thereby ensuring the safety of the valve.

Purpose of American standard ball valve: Mainly used to cut off or connect the medium, and can also be used for fluid regulation and control. Widely used in petroleum, chemical, metallurgy, electricity, construction, heat, water supply and drainage, water treatment and other industries. Valves designed, manufactured, produced and tested according to American standards are called American standard valves. They are suitable for various pipelines from Class 150 to Class 1500. The closing part of the American standard ball valve is a sphere, which rotates around the center line of the valve body to achieve opening and closing. Ball valves are mainly used in pipelines to cut off, distribute and change the flow direction of the medium.