What Are The Uses And Usage Of Stainless Steel Ball Valves?

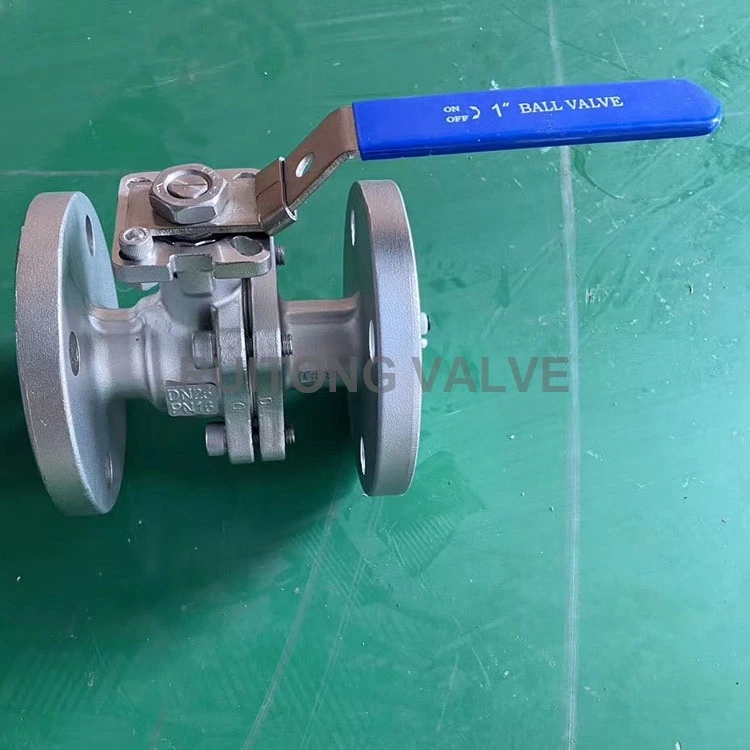

Stainless Ball Valve is widely used in oil refining, long-distance pipelines, chemicals, papermaking, pharmaceuticals, water conservancy, electricity, municipal administration, steel and other industries, and occupies an insignificant position in the national economy. It has a 90-degree rotation action, the plug body is a sphere, and there is a circular through hole or channel passing through its axis. Stainless steel ball valves are mainly used to cut off, distribute and change the direction of the medium in the pipeline. Stainless steel ball valves only need to rotate 90 degrees and a small rolling torque to close tightly. Ball valves are suitable for use as switches and cut-off valves.

Stainless steel ball valves are mainly used to cut off, distribute and change the direction of the medium in the pipeline. Stainless steel ball valves are a new type of valve that is widely used.

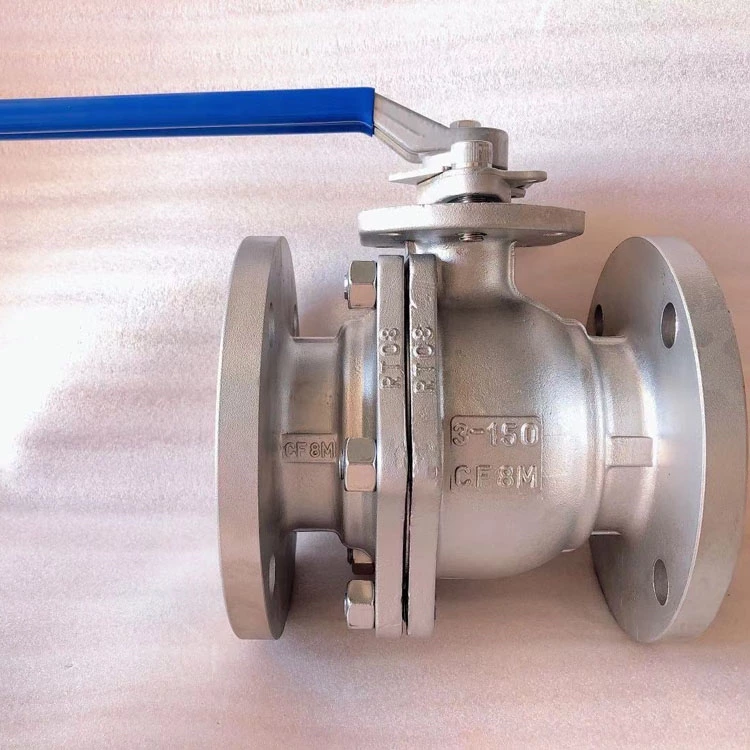

Stainless steel ball valves can be divided into straight-through, three-way and right-angle types according to their channel positions. Three-way stainless steel ball valves are T-type and L-type. The T-type can interconnect three orthogonal pipelines and cut off the third channel, playing a role in diversion and confluence. The L-type can only connect two mutually orthogonal pipelines, and cannot simultaneously maintain the interconnection of the third pipeline, and only plays a distribution role.

The stainless steel ball valve can be tightly closed with only a 90-degree rotation and a very small rolling torque. The completely equal inner cavity of the valve body provides a very small resistance and straight flow channel for the medium. The main features of the ball valve are its compact structure, easy operation and repair. The stainless steel ball valve can be used to control the flow of various types of fluids such as air, water, steam, various corrosive media, mud, oil, liquid metal and radioactive media. The ball valve body can be integral or combined.

In order to ensure the sealing of the stainless steel ball valve when the working pressure of the medium is low, a certain pre-tightening pressure ratio must be formed between the ball and the sealing seat. In the rigid sealing seat, the reliability and service life of the stainless steel ball valve; clamped by the correct selection of the pre-tightening amount of the sealing seat. Lack of pre-tightening cannot ensure the low-pressure sealing of the ball valve: excessive pre-tightening will increase the conflict torque between the ball and the sealing seat, affecting the performance of the stainless steel ball valve; and may cause plastic deformation of the sealing seat, resulting in sealing failure.