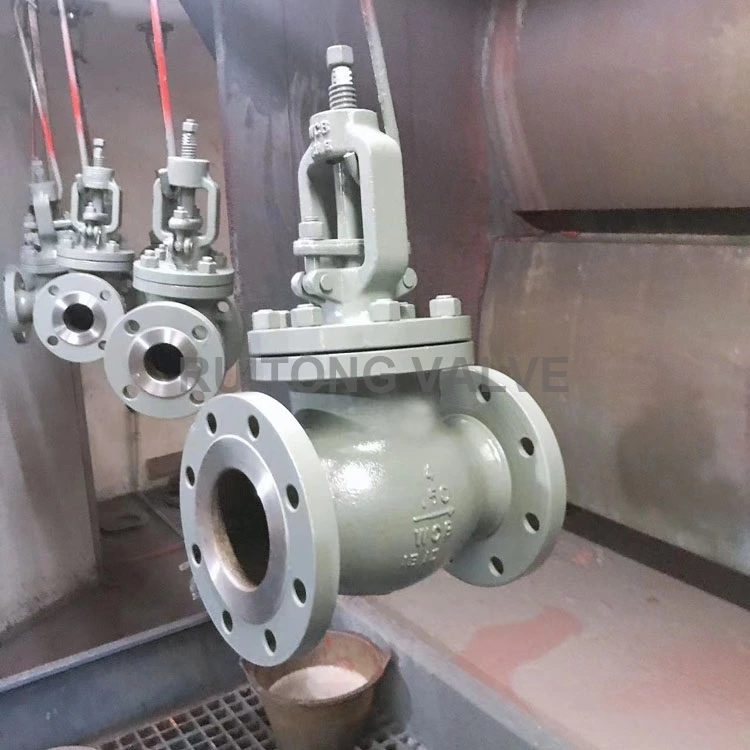

Which Parts Of The American Standard Ball Valve Should Be Checked During Daily Inspection

Here are some parts of the ANSI ball valve that should be checked:

1. Valve seat

During the operation of Ball Valve, due to the infiltration of the medium, the inner surface of the thread used to fix the valve seat is easily corroded, causing the valve seat to loosen, which needs to be paid attention to. For valves working under high pressure difference, the sealing surface of the valve seat should also be checked to see if it is damaged.

2. Valve core

The valve core is the movable part of the pneumatic ball valve when it is working. It is affected by the erosion of the medium and corroded seriously. When checking, you should carefully check whether there is corrosion and wear on all parts of the valve core.

3. Inner wall of the valve body

For ball valves used in high pressure difference and corrosive media, the inner wall of the valve body is often impacted and corroded by the medium, and its pressure resistance and corrosion resistance should be checked in particular.